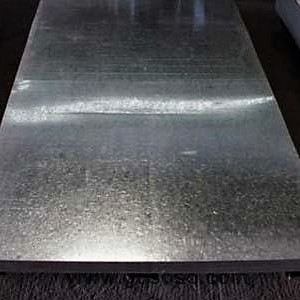

Ipayipi lensimbi engenamthungo

Incazelo emfushane:

Ipayipi lensimbi engenamthungo elakhiwe liyi-hot-dip galvanized, ngakho-ke inani le-zinc plating liphezulu kakhulu, ukushuba okumaphakathi kwe-zinc enamathela kungaphezu kwama-microns angama-65, futhi ukumelana nokugqwala kwawo kuhluke kakhulu kunokwepayipi elifakwe emanzini ashisayo.Umkhiqizi ojwayelekile wamapayipi anothayela angasebenzisa ipayipi elibandayo lamapayipi njengamapayipi amanzi negesi.I-zinc enamathela yepayipi ebandayo yensimbi iyisingqimba se-electroplated, futhi ungqimba lwe-zinc luhlukaniswa ne-substrate yepayipi lensimbi.Ungqimba lwezinc luncane futhi kulula ukuwa ngoba luxhunywe kwi-substrate yepayipi lensimbi.Ngakho-ke, ukumelana nokugqwala kwayo kubi.Akuvumelekile ukusebenzisa ipayipi lensimbi elibandayo njengepayipi lensimbi eliphakela amanzi ezakhiweni ezintsha zokuhlala.

Ipayipi lensimbi engenamthungo elakhiwe liyi-hot-dip galvanized, ngakho-ke inani le-zinc plating liphezulu kakhulu, ukushuba okumaphakathi kwe-zinc enamathela kungaphezu kwama-microns angama-65, futhi ukumelana nokugqwala kwawo kuhluke kakhulu kunokwepayipi elifakwe emanzini ashisayo.Umkhiqizi ojwayelekile wamapayipi anothayela angasebenzisa ipayipi elibandayo lamapayipi njengamapayipi amanzi negesi.I-zinc enamathela yepayipi ebandayo yensimbi iyisingqimba se-electroplated, futhi ungqimba lwe-zinc luhlukaniswa ne-substrate yepayipi lensimbi.Ungqimba lwezinc luncane futhi kulula ukuwa ngoba luxhunywe kwi-substrate yepayipi lensimbi.Ngakho-ke, ukumelana nokugqwala kwayo kubi.Akuvumelekile ukusebenzisa ipayipi lensimbi elibandayo njengepayipi lensimbi eliphakela amanzi ezakhiweni ezintsha zokuhlala.

Ipayipi lensimbi eliphehliwe lisetshenziswa kabanzi ekwakheni, imishini, imayini yamalahle, imboni yamakhemikhali, amandla kagesi, izimoto zesitimela, imboni yezimoto, umgwaqo omkhulu, ibhuloho, isitsha, izikhungo zezemidlalo, imishini yezolimo, imishini ye-petroleum, imishini yokuhlola nezinye izimboni zokukhiqiza.

Ipayipi elishisayo lediphu lensimbi: idiphu elishisayo lepayipi elenza insimbi encibilikisiwe isabelane ne-iron matrix ukukhiqiza ungqimba lwe-alloy, ukuze i-matrix ne-coating kuhlanganiswe.Ukuze kukhishwe i-iron oxide ebusweni bepayipi lensimbi, ngemva kokuchotshozwa, ipayipi lensimbi lihlanzwa nge-ammonium chloride noma i-zinc chloride isisombululo samanzi noma ithangi lesisombululo esixubile se-ammonium chloride ne-zinc chloride, bese sithunyelwa ethangini elishisayo lokucwilisa.I-hot dip galvanizing inezinzuzo zokuhlanganisa iyunifomu, ukunamathela okuqinile nempilo ende yesevisi.Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali phakathi kwe-substrate yepayipi lensimbi elidiphu elishisayo elishisayo kanye nokugeza okuncibilikisiwe kuholela ekwakhekeni kongqimba lwe-zinc ferroalloy enesakhiwo esiqinile sokumelana nokugqwala.Isendlalelo se-alloy sihlanganiswe nesendlalelo se-zinc ehlanzekile kanye ne-matrix yepayipi yensimbi, ngakho ukumelana kwayo nokugqwala kunamandla.

Ipayipi lensimbi elibandayo elibandayo: ipayipi elibandayo le-galvanized electro galvanized, inani le-zinc plating liyi-10-50g / m2 kuphela, futhi ukumelana nokugqwala kwalo kuhluke kakhulu kwepayipi elifakwe emanzini ashisayo.Ukuze kuqinisekiswe ikhwalithi, iningi labakhiqizi bamapayipi abavamile abasebenzisi i-electro galvanizing (i-plating ebandayo).Yilabo kuphela abancane, imishini emidala yamabhizinisi amancane ukusebenzisa i-galvanizing, yebo, amanani abo ashibhile.UMnyango Wezokwakha umemezele ngokusemthethweni ukuqedwa kwamapayipi adonsela emuva abandayo, futhi akuvunyelwe ukusebenzisa amapayipi abandayo njengamapayipi amanzi negesi.I-zinc enamathela yepayipi ebandayo yensimbi iyisingqimba se-electroplated, futhi ungqimba lwe-zinc luhlukaniswa ne-substrate yepayipi lensimbi.Ungqimba lwezinc luncane futhi kulula ukuwa ngoba luxhunywe kwi-substrate yepayipi lensimbi.Ngakho-ke, ukumelana nokugqwala kwayo kubi.Akuvumelekile ukusebenzisa ipayipi lensimbi elibandayo njengepayipi elihambisa amanzi ezakhiweni ezintsha zokuhlala.