Ipayipi lensimbi engenamthungo

Incazelo emfushane:

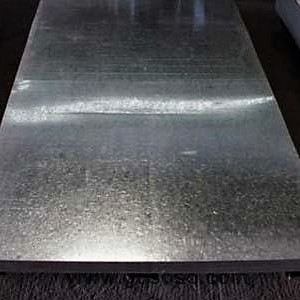

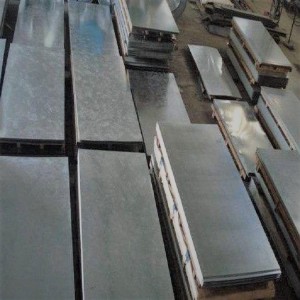

Inani lamapayipi ensimbi angenamthungo lincane kakhulu, lingama-10-50g / m2 kuphela, futhi ukumelana kwalo nokugqwala kuhluke kakhulu kwepayipi elifakwe emanzini ashisayo.Abakhiqizi bamapayipi othayela abavamile bavunyelwe ukusebenzisa amapayipi abandayo njengamapayipi amanzi nawegesi.Ungqimba olunamanzi wepayipi elibandayo lensimbi liwungqimba lwe-electroplating, futhi ungqimba lwezinc luhlukaniswa ne-substrate yepayipi lensimbi.Ungqimba lwe-zinc luncane, futhi ungqimba lwe-zinc lumane lunamathele ku-matrix yepayipi yensimbi, okulula ukuwa.Ngakho-ke, ukumelana nokugqwala kwayo kubi.Ezindlini ezintsha, akuvunyelwe ukusebenzisa amapayipi ensimbi abandayo njengamapayipi ensimbi ahambisa amanzi.

Ngemuva kokukhetha, amapayipi ensimbi angenamthungo e-API ahlanzwa nge-ammonium chloride noma i-zinc chloride isixazululo samanzi noma i-ammonium chloride ne-zinc chloride exutshwe nethangi lesisombululo esinamanzi.Ukuze kuqinisekiswe ikhwalithi, i-electro galvanizing (i-cold plating) ayisetshenziswa kakhulu.Yilabo kuphela amabhizinisi amancane anemishini emincane nemidala esebenzisa i-electro galvanizing, yiqiniso, intengo yabo ishibhile.UMnyango Wezokwakha usuqede ngokusemthethweni ipayipi likathayela elibandayo elibuyela emuva, elingeke lifakwe ugesi ngogesi esikhathini esizayo.Iwukwenza insimbi encibilikisiwe isabelane ne-iron matrix ukuze ikhiqize ungqimba lwengxubevange, ukuze kuhlanganiswe i-matrix ne-coating.I-Hot dip galvanizing iwukucwilisa ipayipi lensimbi kuqala, ukuze kukhishwe i-iron oxide ebusweni bepayipi lensimbi, bese iyithumela ethangini lediphu elishisayo.I-hot dip galvanizing inezinzuzo zokuhlanganisa iyunifomu, ukunamathela okuqinile nempilo ende yesevisi.